Heat dissipation is the energy transfer – in this case heat – from one object to another. More specifically, the energy is dissipated from an area of higher concentration to one of a lower concentration. In many industries, parts becoming too hot is a serious and concerning issue that could affect their bottom line. For starters, excess heat on a part can cause the part to warp out of its necessary shape. Furthermore, in smaller more precise applications heat can be catastrophic for a part causing it to fry and cease operation. Lastly, an excessive amount of heat on a part can cause premature wear and tear on the part. However, with the assistance of UCT’s EXO Nickel Boron coating, manufacturers no longer need to worry about these issues with their parts.

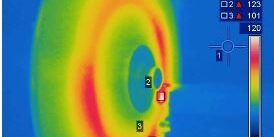

How can something as simple as a coating improve a part’s quality to such an extent? Well, that is all thanks to the grain structure of UCT’s patented EXO coating. The EXO coating does not lay flat onto the substrate like many coatings do, instead it is thousands of small column like structures that stand proud of the material. This columnar structure provides more surface area which gives the heat that is built up a place to dissipate to. Since the EXO provides the part with more surface area to displace the heat with, issues such as overheating can be managed effectively to ensure longer lasting parts.

Another key feature of the EXO’s heat dissipation is the fact that parts coated with it get less hot to begin with. EXO coating delivers a low coefficient of friction, simply put, that means that the surface is smooth enough to require less force to slide an object. With that being said, parts coated with UCT’s EXO have a natural lubricity and level surface to allow for less friction. Less friction means that the heat levels that will affect these parts will not be nearly as catastrophic as it would be without this coating. Concerns such as parts becoming warped from the heat or prematurely wearing out are things of the past thanks to UCT’s EXO.

Heat dissipation is a concern that many manufacturers have with the parts necessary for their day-to-day functions. Without heat dissipation or at least a good system for it, manufacturers would be facing constant down time and repair time for their machines. All of that ultimately translates to time and money lost for the manufacturer, which is never a good thing. UCT’s commitment to help fellow manufacturers elevate their production is the driving force behind all their research and development. If you’re struggling to find a way to improve the longevity of your parts, try giving UCT a call and they might have just the thing for you.