UCT’s high-performance coatings withstand hostile environments

UCT’s high-performance coatings withstand hostile environments

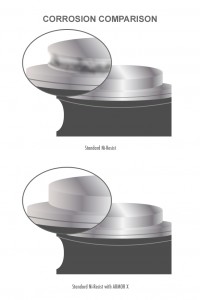

UCT’s EXO coating provides a solid defense against the abrasion, corrosion, and heat associated with oil, gas, and industrial pump operations. Thanks to their superior hardness, these surface finishes withstand dirt, sand, contaminated fluids, corrosive environments, and temperatures up to 1800° F — increasing longevity and performance of coated parts.

UCT’s proprietary, non-line-of-sight, autocatalytic coating bath evenly coats all surfaces exposed to it, ensuring uniform properties while reducing secondary machining. EXO-coated parts enjoy low surface friction and superior lubricity – properties that improve fluid flow and reduce cavitation erosion. Our shear-resistant, non-flaking, strongly adhered coatings are impervious to entrained gases, hydrogen sulfide contamination, and petroleum/distillate products.

By providing a new surface on any coated part, EXO coating may even allow you to choose a more cost-effective substrate – and still achieve superior performance.

Advantages of UCT’s EXO Coating to the Oil & Gas Industry

Advantages of UCT’s EXO Coating to the Oil & Gas Industry

When you specify the EXO coating on mission-critical components in pumps, valves, actuators, and other key production equipment, those parts take on completely new properties. That’s because EXO:

- bonds to substrates with a bond strength of more than 10,000 psi

- coats every contour and crevice of a component’s surface with precise uniformity

- delivers a surface hardness of up to 1,500 HK

- resists corrosion, abrasion, and temperatures up to 1800°F

- reduces friction & heat

- possesses superior ductility, capable of achieving more than 180° bend

Advantages of UCT’s EXO Coating to the Oil & Gas Industry

Advantages of UCT’s EXO Coating to the Oil & Gas Industry